A Comprehensive Guide on Laser Marking Machine Manufacturers

Introduction

Welcome to DP Laser, your trusted partner for all your laser marking machine needs. As the leading metal fabricators in the industry, we understand the importance of high-quality and precise laser marking for various business applications. In this comprehensive guide, we will explore the world of laser marking machines, their benefits, and why partnering with reputable manufacturers like us is crucial for your business success.

The Power of Laser Marking Machines

Laser marking machines have revolutionized the way businesses brand, track, and label their products. With their ability to create permanent, high-contrast markings on various materials, these machines have become indispensable across numerous industries. Whether you require intricate designs, serial numbers, logos, or barcodes, laser marking machines offer unparalleled precision and efficiency.

Why Choose DP Laser?

When it comes to laser marking machine manufacturers, there are several reasons why DP Laser stands out from the competition:

- Industry Experience: With over a decade of experience in the metal fabrication industry, we have honed our expertise in laser marking technology. Our team of skilled engineers and technicians consistently deliver top-notch solutions tailored to our clients' specific requirements.

- State-of-the-Art Facilities: Our manufacturing facilities are equipped with the latest technology and advanced machinery, allowing us to manufacture laser marking machines that meet the highest industry standards. We invest in the latest advancements to ensure our clients receive cutting-edge solutions.

- Customization Options: We understand that every business has unique needs, which is why we offer customizable laser marking machines. From adjustable laser parameters to software customization, we can tailor our machines to achieve the precise markings you desire.

- Reliability and Durability: Our laser marking machines are built to last. We use premium quality materials and rigorous testing procedures to ensure long-lasting performance and minimal maintenance requirements.

- Exceptional Customer Support: At DP Laser, we prioritize customer satisfaction. Our dedicated support team is available to assist you throughout the entire process, from consultation to installation and beyond. We believe in establishing long-term relationships with our clients.

Understanding Laser Marking Technology

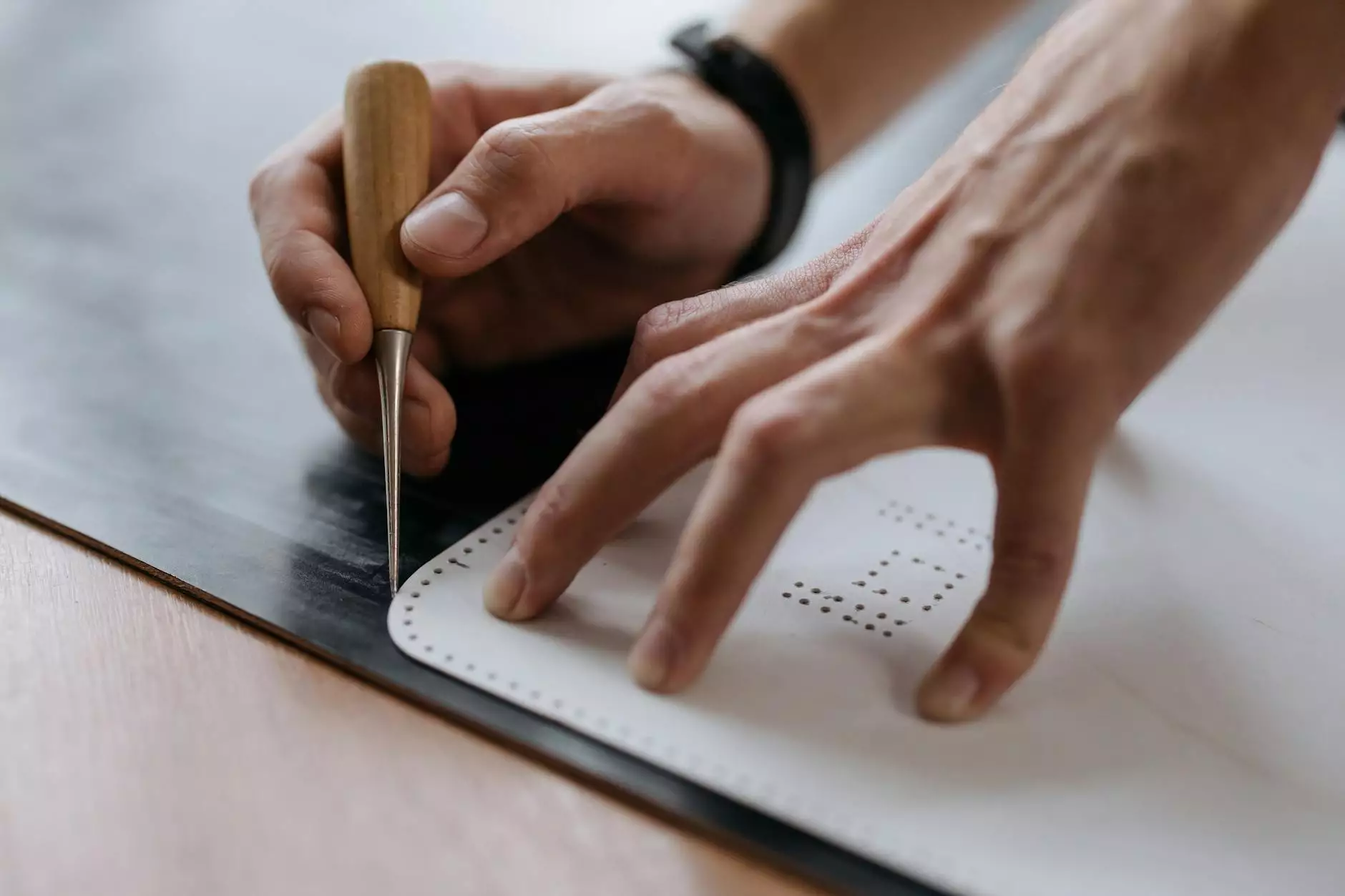

Laser marking machines utilize advanced laser technology to create precise and permanent markings on various materials. The process involves directing a highly focused laser beam onto the surface of the material, resulting in a chemical or color change. The laser beam removes or oxidizes the material, leaving behind a permanent mark.

There are three main types of laser marking methods:

- Laser Engraving: This method involves removing material from the surface to create a permanent engraving. It is ideal for creating deep, long-lasting markings on materials like metal, plastic, wood, and glass.

- Laser Etching: Laser etching is similar to laser engraving, but it creates shallower engravings. This method is commonly used for adding text, logos, or serial numbers on items like electronics, medical devices, and automotive parts.

- Laser Annealing: This method involves heating the material surface without melting or engraving it. It produces a contrasting color mark by altering the material's reflectivity. Laser annealing is often used on stainless steel and titanium materials.

Benefits of Laser Marking Machines

Laser marking machines offer numerous benefits for businesses across different industries. Let's explore some of the key advantages:

- High-Quality and Precise Markings: Laser marking machines provide unmatched precision, ensuring clear and accurate markings even on intricate designs or small components. This allows for easy identification, branding, and traceability of products.

- Durability: Laser markings are resistant to wear, fading, and smudging. They can withstand harsh environmental conditions, making them ideal for outdoor applications.

- Product Customization: Laser marking machines allow for customization, enabling businesses to add unique identifiers such as serial numbers, barcodes, or QR codes. This enhances product traceability and helps prevent counterfeiting.

- Efficiency and Speed: Laser marking machines operate with remarkable speed, making them highly efficient for high-volume production. Fast processing times ensure minimal downtime and increased productivity.

- Non-Contact Process: Laser marking is a non-contact process, eliminating the need for physical contact with the material. This minimizes the risk of damage, ensuring consistent quality throughout the marking process.

Industries Benefiting from Laser Marking Machines

Laser marking machines find applications in a wide range of industries:

- Automotive: Laser marking is used for component identification, VIN numbers, and branding on various automotive parts.

- Medical: Medical devices and instruments are often laser marked for product identification, tracking, and ensuring patient safety.

- Electronics: Laser marking adds permanent markings to electronics components, PCBs, and consumer electronics.

- Manufacturing: Laser marking is crucial for product branding, traceability, and inventory management in the manufacturing sector.

- Aerospace: Aerospace components require durable markings for identification, ensuring quality control and regulatory compliance.

Conclusion

DP Laser is the leading choice for businesses seeking reliable and high-quality laser marking machines. With our industry experience, state-of-the-art facilities, and commitment to customer satisfaction, we deliver unparalleled solutions to meet your marking needs. Embrace the power of laser marking technology and elevate your business to new heights. Partner with DP Laser today for all your laser marking machine requirements!